|

The Internet's Largest and Fastest Growing Engraving Community

Discuss hand engraving using basic to the most advanced methods and equipment

Forum Members: 14,761. Welcome to our newest member, AnicaLin

EngravingForum.com -

Domain since Feb 7, 2003

Graver Video Conferencing is empty Join now!

Graver Video Conferencing is empty Join now!

|

|||||||

| ENGRAVING TOOLS - Paypal accepted | Classes | Glossary | Feedback | Tips | Sharpening | Bulino | Videos | Forum Policies |

|

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

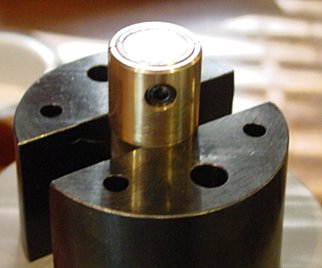

It appears that coin carving these days is more popular than ever. Steve's excellent tutorial is evidence of this, but holding the little rascal can be tricky. I've seen guys use pitch, hot glue, or any number of tricks to get the coin stable and secure. I thought that perhaps their was a better way! I dug into my closet coin bucket, and gathered a handful of Jefferson nickels, both old and new, as well as some buffalo nickels from my own coin collection. All of my Buffs are fairly worn... they were bought by a young boy (me) a long time ago at coin stores and shows, and I couldn't afford the nicer specimens!

Anyway, a few days ago, I designed and machined a prototype workholding device, and sent some pictures to Steve. He liked the device. I asked him if it would be OK to offer them for sale to the membership here, and he gave me his approval. My goal was a fixture (I'll call it a CC, for Coin Collet) that would FIRMLY hold a nickel, and present either surface to the engraver, for any operation: roughing, background removal, and finer cuts and shading. The coin can be installed and released in seconds. The nickel's surface is presented above the holder's rim, meaning the CC does not get in the way of the engraving operation. A single 8-32 socket head cap screw secures the coin by collapsing the body of the collet around the rim of the nickel. No set screws touch the nickel, and it is unmarred by the collet. To achieve this sort of clamping requires an accurate bore (hole) for the nickel. When I put a good micrometer across a dozen nickels, both old and new, I was amazed at the variation in diameter. I don't know if they left the mint this way, but it is significant, on the order of +/- 0.005" from the average diameter. This means I needed to create a double-ended fixture. One end of the fixture will be the large end, the other a bit smaller. Between the two ends, it'll clamp pretty much any nickel out there, short of one run over by a train! You won't need a micrometer to figure out what end to use... start with the small end, and if it seats itself before tightening, use that end. If it won't install, switch to the large end. These pictures are of the rough and quick prototype, and I do apologize for the quality of the shots. I didn't even finish cleaning up the swarf (small metal chips, etc) from the inside. The finished CC would be clean, and sport a glass bead-blasted exterior finish. I was going to execute a better prototype, and take some nicer shots, but I ran into a bit of a time crunch with work. So I decided to post these, and see what interest there might be in such a fixture. The round stock is turned, bored through, and then precision bored each end for the two different diameters. It is then split, and drilled and tapped for the set screw.  The CC, plus the modern Jefferson/Buff nickel, are resting on the jaws of my engraver's vise. This gives you an idea on the size of the unit.  Note the double, or stepped, recess in the body of the CC. This step ensures that the CC is holding ONLY the very outer rim portion of the coin. If you have tall engraving, inlays, or an irregular surface, there is no problem, as the surfaces of the coin don't touch the fixture... only the rim and perhaps ten thousandths of the coin faces make contact.  With the nickel installed and secured, it is accurately and securely held in the V-guide of a standard engraver's vise jaw. When removed from the vise, and reinstalled, it returns to exactly the same spot it was earlier. Scope users will appreciate that. There are refinements that can be made. The CC can be turned and bored from perhaps blued steel for a lifetime of coin workholding. A rim can be left in the outer diameter of the CC body which will register with your vise jaws, meaning the CC can be removed, reinstalled, and it will retain the exact Z-axis relative to your setup. It'll be in focus, and at the correct height. Finally, this system is not limited to nickels. A similar unit can be machined for any sized coin, medallion, or other round object. I was thinking about making a run of these for the hobo nickel enthusiasts, but before I actually get to work, I was wondering if this was something that would appeal to you coin engravers out there, or if there was some refinement that could be engineered into the device that I, a beginning engraver, might have missed. The price would be somewhere between $20 and $30 for a standard 6061-T6 aluminum double-ended collet. Custom machining or diameters would be reasonably priced, as these are all handmade anyhow, and a different diameter simply means that I must start with larger stock. Sound good? Steve L. gave it a preliminary thumb's up, as he and I both think it would be a useful addition to the coin-carver's arsenal.

__________________

Kurt |

|

#2

|

||||

|

||||

|

I would be interested in one of these.

David

__________________

David Gruber WWW.Sharpgraver.com "The democracy will cease to exist when you take away from those who are willing to work and give to those who would not." Thomas Jefferson |

|

#3

|

||||

|

||||

|

I wannnnn it I waannnnn it

I have one quite similar Dave London milled out for me I can see where it might need a little modification Heck i checked your site - yousa wizard so here's my thoughts Keep in mind I don't know much about the material you are using and I am not a machinst. All nickels are not the same size Some of them are round some are not - I have tried making similar gadgets out of steel wigets supplied by various vise makers - i think they refer to them as button holders. Current vise came with a set machined to fit a nickel. But not all nickels and unfortunately not covering the entire circumference as your device.. The rim height varies Working around or over a rim is a pain in the ass. Some employ a washer or a piece of wire bent to a ring to rest the graver on. I tried it but it's a pain too. Better to learn to be careful. But considering the varience in the thickness of the coins - what potential for a table within a sleeve that could be adjusted for height. Gee I think I have reinvented the push up opsicle. Anyway same concept. It would be nice to drop the coin into a recess for some things , flush for others. The hardness of the coin varies. Hence the issue of slippage and shavings. If crud gets in between and you tighten the coin up those shavings would naturally have to be imbedded in one thing or another. Usually the coin rim as it's going to be the softer of the two. The use of aluminum on a nickel makes me sweat. If it slips on the coin and it might - transfer of any aluminum or any metal gall to a buffalo nickel rim or other coin would be an issue. 2005's no big deal. The blued steel makes good sense. I have seen some in brass. Steel would be nice aside from the varience in diameters but with a disposable inner liner or inner ring of some kind in varying sizes might make sense too. Then you could bore out one big vice with capabilites for differnt ssize coins ranging from penny to morgan silver dollar and if it gets crapped out replace it with a new one. The backside of the coin is worth more than the front. Any dings scraps scratches or pressure marks there destroy the job Threading a hex bolt into aluminum - I could see myself stripping that very soon. Lot's of nickel shavings do nasty wonders to the threads of my vise jaws. I would imagine they would trash the bolt soon as they worked their way into the threads. So some different way of applying compression. Either all the way through without threading. An aircraft nut on a curved washer? Experience has proven to me the holding power of the V notch for a round widget is not great. Making the lower half square or triangular would be more solid and prevent rotation of the assembly. If you consider the force of the dead blow tungsten piston mod hitting a nickel - it's a hell of a whop. More so on a morgan. There is nickel carving and then there is Nickel carving. Newbies will be using off the wall coins and will be a bigger market and who knows what that would mean. Too many nickel carvers and the market will die. Top cutters don't use cheap coins. Neither do they cut just the common coins you see on the net. The price range for nickels varies widely. But it is not rare to start with a 300 dollar nickel and it can go higher. Other coins higher yet. So you can see why the concern for solid holding. Each coin is it's own little pain in the ass with variences. It would be wonderful if you could come up with something that would allow safe holding while working on the edge of the rim. (we do get neurotic cutting these things at times NOw if you wanted to go severly off the deep end make o set of vise table tops to do the same thing. Then they could be dropped in the pin holes and be a no brainer for someone dumb like me who can't tell one hex wrench from another. But in general we cut nickels but not all flavors of them - wheat pennies - morgans - gold pieces - copper silver gold rounds (blanks) and prestruck coins if you could get this whipped by tomorrow I will put up an alter in my studio and burn incense to a picture of you every day. And I would order one too!!! (feel free to yell scream and jump up and down now) Cant wait to see what you come up with. Can you hand one of those turbine engines you build on my classic so it will go faster? Damn must be nice to be a machinist You could call it a CCCC

__________________

CoinCutter Last edited by Steve Ellsworth; 04-29-2007 at 11:32 AM. |

|

#4

|

|||

|

|||

|

Kurt,

The fixture looks great. I do have one suggestion. I made one similar to this but I used octaganal stock so the fixture has flats to clamp on. That way you do not need a vise with a V groove in the jaws to hold it. Ray |

|

#5

|

||||

|

||||

|

Wow, Steve and Ray, that's a lot to digest, and that's just the kind of info I need, not being a coin cutter myself. I was daydreaming today while at work, and was thinking bronze would be a good choice. The material is not a big contributor to the cost, it is, like so much else in life, the labor involved.

Steel would be ideal if it were not for the rust issue. Stainless would be a good, durable choice, but it is always a bit trickier to machine than many other metals. The more I think about it, the more I like bronze. Soft enough to not mar or nick, yet durable, no rust, and it simply looks nice too. Steve - if someone were to start with a $300 coin (and go UP from there!!) it'd make sense to invest in a holder that's machined purely for that coin. That would avoid two problems you mentioned - variations in diameter, and the thickness of the rim. Given a coin of known diameter (let's say it 0.8730"), you could make a double-ended fixture with the same diameter on each end, but with the only difference being one end completely recesses the coin below the rim of the collet for max holding power, and the other end raises the coin slightly proud of the collet, so you have access to the rim of the coin for light cuts. In either case, it could have the double-recess that would keep the reverse in zero or absolutely minimal contact with the collet, and that only on the area very, very close to the rim. The inner recess can probably be bored so that the only contact is the rim plus a hair's width extra, just enough to keep the coin from simply falling down into the fixture. If a coin is badly out of round, there's not much you can do other than to scan it and use a CNC machine to pocket a collet device to the exact shape of the coin. I'm not too concerned about the durability of the aluminum vs. mild steel, when it comes to the threads for the clamp bolt . Modern wrought aluminum alloys, especially 7075-T6, have yield strengths superior to that of mild steel. When properly threaded, with good, full threads, the head of that steel socket head screw will shear off of its body before stripping those threads. But I keep going back mentally to bronze. I just love bronze, both mechanically and aesthetically. There's an alloy called aluminum bronze (sounds weird, but it's great stuff) that is significantly harder and springier than a traditional copper/tin bronze alloy. That might be the ticket. Both you and Ray mentioned the need for either a hex or square shape. I can easily see the advantages of that. I'll crank one up out of bronze and include a shape that would do what we seek.

__________________

Kurt |

|

#6

|

|||

|

|||

|

Kurt,

I made mine out of ocatagonal brass stock, I made it a .002" oversize and I split it on both sides. I have not found a nickel yet that would not fit nicely. Before I took it out of the chuck I tried a couple dozen different nickels and they all fit fine. THe extra .002" gives enough that if a nickel is slightly oversized it still fits and... By splitting both sides if you do have one a few thousands under the extra slack is easily taken up without having enough slop to damage the coin. There is not enough difference in these coins to need individual holders. When I tested the two dozen when making my fixture they all measured between .833" and .837" .004 is not enough difference that it cannot be taken up by a double split collet. I would think that a sampling of 24 coins would be plenty enough to get 99.99% of the coins out there. I have found a few newer nickels that went down to .832" but your still only talking about .005" total range. That is beyond the repeatablity tolerence range of most lathes, I know your lathe probaly is tighter than that but you get my point. If your collet were machined to .839" and you split each side it would hold any nickel you would ever find unless the nickel had bee dammaged in some way. Ray Ray |

|

#7

|

||||

|

||||

|

Thank you, Ray, I noticed the same thing. Most nickels (and probably any other modern coin) come from the mint with a fairly tight range of diameters, with an occasional flyer that's way out there. If the collet is engineered correctly, it'll close. It's not ideal if it needs to pinch down on something significantly smaller, but it'll still work.

Given the input so far, I cranked out another, from Bronze.  This one I split both sides, used a larger hex screw, and milled 4 flats on the base so that it'll secure nicely in any engraver's vise.  As a fun test, I installed a modern nickel and put it in the lathe. I could almost hear poor Mr. Jefferson shrieking "Nooo-ooo-oo" as I erased him from the field.  The collet held up nicely. This one I bored out what I'd call sloppy, but there's more than enough clamping action to secure the coin. Only a real acid test will tell, but I'm confident - you'd have to apply a cold chisel and a carpenter's hammer to move this coin with the screw set.  Finally, how it'd look in a vise:  I have no desire to bore people on an engraving site with a lot of machining stuff. I genuinely want to contribute in some small way, and maybe this sort of thing might help some people having trouble with workholding. Steve L., please pull the plug anytime. I'm not here to hawk stuff, and I rarely machine for $$; I'm here to learn how to engrave from the masters of the art.

__________________

Kurt |

|

#8

|

||||

|

||||

|

boring my ass

pull the plug never can you move next door to me? this is cool stuff check your mail

__________________

CoinCutter |

|

#9

|

||||

|

||||

|

Hi Kurt,

I'll never tell you to stop! All of this is engraving and engraving tool related. I like good tools and ideas! When you have the first batch of these ready to sell, feel free to sell them on the forum. I could also have a web page made for them on the AirGraver site where people could contact you and purchase direct. Steve |

|

#10

|

||||

|

||||

|

Kurt

Tools did someone say tools:willy_nilly: Good job put me down for one. Dave |

|

#11

|

|||

|

|||

|

Kurt,

After you take care of all the orders you've already gotten, we'll take a dozen... just send me your contact info and a bill. Brian P. Marshall Stockton Jewelry Arts School Stockton, CA, USA 209-477-0550 instructor@jewelryartschool.com jewelryartschool@aol.com |

|

#12

|

|||

|

|||

|

if you keep it under $3,000.00 us, yeah i'll buy one.i already stole enough grocery money to get the airgraver! a couple g's more, my sweetheart will never miss it ! details to monk45@verizon.net

|

|

#13

|

||||

|

||||

|

Send Brian 12 bill him for 13 send me the extra. Charge him the postage too.

None of this would be possible if it wern't for that guy dressed up like an Indian on the nickel. We should all bow our heads in a moment of remembrance.  That's long enough. Back to work.

__________________

CoinCutter |

|

#14

|

||||

|

||||

|

Seriously - base it on the size of an AU grade Buffalo nickel.

What kind of camera are you using. Pics are really nice on this end

__________________

CoinCutter |

|

#15

|

|||

|

|||

|

I AM serious! And if if Steve wants an extra, I'll cover that too... Cheaper than buying him a nice dinner for this lil' education he's givin' us!

Brian |

|

#16

|

||||

|

||||

|

Dinner

Did I hear DINNER Would that be in Europe Gee now go look at the last half of the tutorial - it's up Let me know if any of it doesnt make sense or if i said anything stupid or politiacally incorrect - how the hell do they spell that politically word anyway?

__________________

CoinCutter |

|

#17

|

||||

|

||||

|

It's a go, then. Thanks for the positive replies! I've got a string of work days to get through first, and by "work", I mean the stuff that puts food on the table, nothing enjoyable like engraving or other shop activities. I'll tool up for a couple of runs, gather the raw stock, and get going. There'll be several options or grades of holder, from a basic single-ended aluminum collet for casual use, all the way up to one machined specifically for a single, high-grade coin, to the customer's specification.

I haven't priced AU Buffalo nickels in a long time, and I don't have any here with me... all I've got is my boyhood collection of Good to Fine common date buffs. If someone has a really good micrometer that they trust, AND several VF to BU buffalo nickels, if he or she could give me some accurate diameters for those coins, it would help tremendously. As I mentioned in post #1, a handful of nickels, both old and new, showed a diameter variation of nearly 0.010". While that doesn't sound like much, it's a pretty large range for a collet-type device. For a basic version, I'd probably go to a 90th percentile on the large end. For a gem coin that will be turned into a hobo masterpiece, it would be best to measure the actual coin, and dedicate a collet to that coin specifically. We'll deal with that when the time comes. Steve, I am using a Sony MVC-CD300, set on MACRO, low res (640 X 480), and the pictures are cropped and sharpened with Google's Picasa2 software, the best freeware photo software I've ever encountered. I get lucky with the shots because the photos are well-lighted to begin with... I've got a pair of gooseneck halogen lamps to help me with the machining! :D Take care all!

__________________

Kurt |

|

#18

|

||||

|

||||

|

send me a address ill send you and AU

__________________

CoinCutter |

|

#19

|

|||

|

|||

|

Hi Kurt.

Wonderfull little fixture and great photos. Just a thought, if you don't mind. Make them to sit lower in the vise. That makes most things easier to work on. That is why hex stock would be better IMO. This way they can be set in the vise at a height to suit the individual. John B. |

|

#20

|

||||

|

||||

|

John, I think you're right, hex or octagonal stock would be best. I'll need to pick up a hex 5C collet to machine them, but they'd be easier to work on, both for me when I create them, and the end-user as well.

For those who PM'ed me, I'm going to start plowing through them, and I apologize if my response seems a bit slow. Thanks for all the interest so far in this project. I want to make something that will work well and provide years of effective coinholding for the coin carvers out there. I'm making a list of interested parties and will be in touch individually. Kurt |

|

#21

|

||||

|

||||

|

Guys,

You Really Make Me Wan;'t to Get Into Coining Carving, I Do A Lot Of Ivory and St/St, But Not To This Quility,!! And Also No Coins to Carve Out Here, I see All These 1835 Coins, Come On Guys Where Do You get Them!!?? We Will Get Put in Yale to Cut Any Monitory Currency!! ChriB Help I Want!! |

|

#22

|

||||

|

||||

|

kurt read your mail box

__________________

CoinCutter |

|

#23

|

||||

|

||||

|

Hey Kurt, I am interested in getting one of your coin collets if you are still making them. I did one coin and think that I'm hooked already. At the very least I want to play with them some more and I'm a tool junkie. Check your e-mail and give me a shout back to my e-mail address or send me a pm. Thanks, Jon

|

|

#24

|

||||

|

||||

|

Very quick update on the collet project. Steve E. has tried two variants. They performed well in certain areas, in other areas there were shortcomings, especially extraction of the coin. To make a collet hold a coin firmly enough for some real roughing means it is tough to remove. It also sat too high up in the vise.

I've got a plan for a two-piece coin holding system, but haven't executed it yet. I'm so busy right now, with both my normal job, AND trying to teach myself some decent engraving skills. It is not abandoned, just on a temporary hold. I will try hard to come up with something that will do the job, and at a cost that won't make it prohibitive. To those interested, thanks for your patience. Kurt

__________________

Kurt |

|

#25

|

|||

|

|||

|

The one I made up out of hex stock - while waiting - has a hole running through the center... I didn't use a screw to tighten it, I am relying on pressure from the vise jaws. Simple enough to tap the coin out with a Delrin or wood dowel. Maybe that'll help?

Brian P. Marshall Stockton Jewelry Arts School Stockton, CA USA 209-477-0550 instructor@jewelryartschool.com jewelryartschool@aol.com Last edited by Brian; 07-04-2007 at 12:50 PM. |

|

#26

|

||||

|

||||

|

OK, I give, Where's the COST as in $$$$. Did I miss it somewhere?

|

|

#27

|

|||

|

|||

|

he's all hot air! 3 months ago i offered him over 2 thousand bucks for one of these and he didn't even reply to my e-mail !!

|

|

#28

|

||||

|

||||

|

I'm feeling potent guilt-vibes flowing across my internet connection! :D Seriously, I do apologize. I got people all pumped up, and it was rude of me to not follow through in a firmer, and more methodical fashion.

Danny, there is no cost yet. Once the design is finalized, I'll let everyone know. I absolutely refuse to sell something that does not perform well. There are guys carving mint-state coins worth hundreds of $$, and it's critical that it doesn't slip under heavy cuts, AND doesn't mar the coin. I am a hobby engraver, and a hobby machinist too. I have a normal (boring, long hours) job, kids, etc and just like everyone else, there's never enough time. How about this? The fastest and cheapest setup to produce is going to be a single-end pinch collet in aluminum. I'll make a few of the original design in 2024 or preferably 7075 aluminum, and get more of them "tested". Be aware: Nickels seem to really vary in diameter, a lot more than I ever expected them to (almost 0.010" / 0.25mm), and for this type of collet closure device to work, it needs to be as close as possible to the true size of the coin. Ideally it'd be within 0.002". To make it accept, say, 85% of the nickels out there, I need to bore it open on the largish end of the size spectrum. This means it might not hold as well as one would like. But it's worth a try. I'll get some out to a few guys and get some more feedback. Maybe I won't need to go to some complex 2-piece design.

__________________

Kurt |

|

#29

|

||||

|

||||

|

I'm just curious why you wouldn't just hot glue the coin to a chunk of something? I use it all the time and think it's great. I keep scraps of various sizes and shapes of Corian scraps around to glue stuff to.

Otto

__________________

Otto Carter Abilene, Texas www.ottocarter.com  Aside from that, Mrs. Lincoln, did you enjoy the play? |

|

#30

|

||||

|

||||

|

Quote:

but it's a bit risky for serious work - invariably covers up the rim doesnt hold up to impact easy to scratch the coin trying to get the stuff on and off nasty messy ickky stuff tastes terrible thre is a lot more to the art than meets the eye what you dont carve and dont scratch is just as important as what you do change the metal is soft - once dinged its crap forever very hard to fix mistakes you think harley riders are picky - try coin collectors whats a good average harley bring now 20 grand? thats four good nickels in someones high end collection so we use as nice a vise as possible

__________________

CoinCutter |

|

#31

|

||||

|

||||

|

If I may make one more suggestion.

When making the "holding circle" put in a 1 deg (or less) taper. It will always be forcing the coin "in". This will also 'grab' a coin that is too large or too small better, and not have a tendency to wear (loosen up) as quickly (longer life). Also, If you have a nominal size for the initial bore, the tightening bolt should clamp up on almost anything quite nicely. I would think that the cut is bigger than the coin tollerance. If the coin is bigger than the opening then a small flat screwdriver would spring it open more and the too large coin would fit in it and be clamped up. To release a "normal" coin, a vertical shaft with a soft tip that has a slot in it that rides on 2 pins or a vertical guide can be used. A rod is then inserted into a side slot, goes to the bottom of the vert. shaft, is pushed down, shaft goes up and out comes the coin. Of course 2 opposite slots cut in the holding crown would work, but where is the fun "engineering" in that! |

|

#32

|

||||

|

||||

|

wow that was a mouthful!

i would love to see a picture of that device it sounds pretty sophisticated

__________________

CoinCutter |

|

#33

|

|||

|

|||

|

I've had the hots to make a bit of a different style of internal holder so that I could engrave the sides of rings more easily for quite a while now and this thread gave me a really cool idea of how to make a coin collet as well as an internal collet system at the same time, (using different inserts). Since I like heavy tools I figured that I'd make this mostly from a pre-existing tool that could do double duty. That tool is an ER32 collet and collet holder that's been modified to fit my engravers block by cutting off the spindle end and doing some milling to shorten the whole affair. Fabricating a set of inserts in brass to fit the collet and provide either internal gripping for rings or external gripping for different sized coins would complete the arrangement. The beauty of these collets is that they are heavy, durable and reasonably priced. The inserts will look something like Kurt's collet, but have 8 slots matching the slots on the ER collet and fit closely to both the ER collet I.D. and the coin O.D., tranfering the griping power of the ER collet through the brass insert to the coin. The ER collet system comes with a built in collet removal as the collet is captive in the cap nut and offers a closing range of .04 inches. I think that with the right design on the insert, (not too stiff), that the collet could be closed on the coin by hand and offer a fine, evenly distributed grip on the coin with no chance of marring the coin and offer easy removal since the coin would be slightly loose when initially inserted. I've shown a penny stuffed into the steel collet where the insert would go. I'd start hacking up this collet holder right now, but I use it as is and I don't want to mess it up, so I'll have to get this idea rolling next week when some different parts come rolling in. Thanks for the boost to the idea factory Kurt !

Michael E. |

|

#34

|

||||

|

||||

|

I think you machinists have an unfair advantage over us coin carvers

and the rest who struggle to get tooled up just to engrave. SO, in order to even out the playing feild I think you guys who are machinists should pay the piper and make all the tools we poor teachers need to teach you machinists how to engrave. Sounds fair does it not? We teach you all you ever wanted to know about transfers techniques all the behind the scene stuff that you are chomping at the bit to learn, the things that will save you years of painful learning on your own. All you have to do is make us pretty self centering vises, microscope booms and head rests that dont wobble, pretty collects and gadgets. Free shipping too. in return we tell you all, give you our home phone numbers and hours that you can call and ask as many questions as you want. For complete turn key bench sets made in exotic materials and hydrolically plumbed to do anything we want we allow you access to our web cams and if you are luck we even tell you where the fish are biting. And - if you pregrind our gravers for us we will show you how to actually make a buck doing this stuff. Nice collet. If the coin falls out on its own and dosen't require a push from the back and the sections of the collet dont show a pattern on the rim after tightening down or leave the slightest trace on the rim you are on your way. Looks like the begininng of a new type of competition!! I love it!! Keep up the great work. However _ I think you guys are making this way to complicated got to be a simple/universal way

__________________

CoinCutter |

|

#35

|

||||

|

||||

|

Say - What about making the "holder" way oversized then using that heat setting stuff. It could be used to match the coin perfectly, leave absolutely no chance of marring the edges, the coin is easily removable because the "Holder" can be sprung apart (the "plastic" stuff is also cut so it stays with the holder). Best of both worlds. It can be reshaped to fit anything - even flat sided coins, is cut so it moves with the holder, and is gentle to the edge what more is there?

|

|

#36

|

||||

|

||||

|

Say Michael E:

If you made a hunk of steel to hold the collet, and the base had two bearings in it - you'd be all set! One whole complete coin holding unit! Shouldn't cost more than $900 to hold a nickle! hahaha |

|

#37

|

||||

|

||||

|

Wouldn't it be cool if humans could trade skills? I'd happily swap some machinist skills for engraving. You could post in on eBay. "Trade: 40% of my skill in oil painting, for 35% of a certified master auto mechanic skill set." Then you could stick your fingertips into a box which would suck away your skill and send it over the internet to the other guy.

Machinist-types are infamous for over-engineered and expensive solutions, like Dilbert. My next attempt to stay within this stereotype is a set of precision steel blocks which will fit into a typical engraving block, like a magnablock. It'll have two halves, with dowel pins for alignment. Picture a sandwich of two steel blocks, shaped rectangular or square, maybe 3" tall. On the top, I plan to bore out a nickel recess, which will have further boring to clear the reverse of the coin, so it will grip only the rim. Two socket-head cap screws will secure it together, then the whole thing gets dropped between the jaws of the engraving vise. Here's a 5 minute 3D model (Rhino 3d software) of the concept with no screws, dowels, or dimensional accuracy, just enough to get the concept: Thoughts? Please don't tell me I'm overengineering this. That makes me sad.

__________________

Kurt |

|

#38

|

||||

|

||||

i thought i told you about this concept early on but i may not have being the space case i am. I have one in delrin round stock that Dave London whipped up but it needs some work in the slippage department. but this shape would work - as long as it didnt crack over time from flexing It belongs to the famous Clifford L. Kraft wonderful guy and great nickel carver. His website is http://www.paulbunyan.net/users/pckraft/index.html check out his work and enjoy.

__________________

CoinCutter Last edited by Steve Ellsworth; 07-12-2007 at 12:03 PM. |

|

#39

|

||||

|

||||

|

Thanks Steve, I do remember this style you mentioned and it was always hip-pocketed as a good working solution. Mine would be different in that it would be two pieces, dowel-pinned together, and probably a pair of 1/4" cap screws to clamp the two. The bore would be further relieved so only the rim would be gripped. I know you dislike extra screws, but I think in this case it'd be worth it, as the grip would be seriously strong.

__________________

Kurt |

|

#40

|

||||

|

||||

|

I am sure you know what you are up to better than i !

Considering the mess of fine chips powder and other crud from the nickel i bet the dowels jam up - threads will get to be a mess too. Thats why I lean to something tied directly to the vise top let the vise screw do the work - As it is i have to vacum out a load of crap in the vise every other day as it jams up the threads in it - Anything with more screws and handling makes one more mess to clean or strip out and another option to get a sliver in the finger after you carve a fewhundred of these little things you will know what i mean they are a pain in the rear and dont forget - Morgan silver dollars Wheat pennies The newer nickels Misc gold pieces how about something in spring steel that conforms to all sizes

__________________

CoinCutter |

|

#41

|

|||

|

|||

|

Quote:

Over-engineering is the name of the game. Once you've made the most elaborate, Rube Goldberg type device possible... in your mind...you can then start knocking off all of the stuff that isn't needed or is too expensive. At least you've covered all of the bases that you can think of and decided what really matters and what doesn't. Speaking of Rube Goldberg, I never thought that he really existed. Turns out he did, very interesting: http://www.rubegoldberg.com/ |

|

#42

|

||||

|

||||

|

problem solved

i have a knife vice i think ill carve knives

__________________

CoinCutter |

|

#43

|

||||

|

||||

|

Hey Kurt B - the dowel pins have a problem. The bottom needs to be a "hinge" so that the top springs in. If it doesn't the coin will have a great tendency to come out because the bottom will wedge in further than the top, so the coin holding section will have a negative taper (small at the bottom larger at the top). The pins sound good but will cause taper and coin popping or moving. A long thick cut works, like on the square one because the clamps squeeze the top and put a positive taper on the coin holding it in place.

Just how simple is this thing? Still think final "seating" should be some of that heat set stuff, with the holding area having notches in it to retain the stuff after it sets and the coin removed. |

|

#44

|

||||

|

||||

|

Danny, I was going to bore the blocks as a unit; then, when separated, face mill about .002" off each block where they meet, leaving a narrow band of material at the bottom. That would force any piching action to act on the coin alone, plus the band.

Another option is to use a 1/8" ball mill to run a groove at the bottom of one block, a corresponding groove slightly shallower in the other block, and use a 1/8" dowel pin layed in the groove as a hinge point. That would act as both an alignment feature, and a hinge. It could be made one piece, but I don't like being forced to use a fine slitting saw to hack through 3" of material, leaving it intact at the bottom, like the one in Steve's picture. Apparently the serious cutters use a lot more force than I'd ever have imagined, so I really want to make it clamp hard, yet not mar the coin.

__________________

Kurt |

|

#45

|

||||

|

||||

|

if tapering the coin recess would distort the rim or leave a mark junk that idea

a single lever device lock/release device would be nice - i can see a recess of 3/4 the circumference of the coin or a little less and the remaining section which does the clamping moving into the coin via lever action even my vise will not stay clamped on anything for too long considering the impact of the classic even at 50 lbs I would have to say while you are at it compensate for vise slop - hell my peppe did a better job holding than the grs but skip has it now. damn (hope SL doesnt see this post or he will be tring to sell me one of his ) i will tell you this time is a factor dinking around with any gadget -screws plastic heatform etc is not desireable take a look at the watch vise - that might provide a take off i have the knife vise and it works nicely so there is something going on there however the base line secret to all this is very sharp tools remember we are not engraving in the traditional sense we are chasing and cleaving metal - moving it around beating the hell out of it i am surprized my classic hasnt died considering all the crap i put it through it is 99 percent ofthe time pedal to the floor and I rarely take my foot off the pedal

__________________

CoinCutter |

|

#46

|

||||

|

||||

|

Yea, Kurt I can see where you are going. I think that a band saw blade would give the clearance and clamping force needed to do the job. A slitting saw (in thousands) would be too fine, my guess. The greater the movement, the greater the "various" diameters that can be accomodated.

Please make up about 20 and pass them out for evail - :>) haha |

|

#47

|

||||

|

||||

|

Kurt

The one that Steve E mentioned was made from delrin around 11/2" dia, I used a boring bar for the coin pocket and split the unit with a band saw works ok If you are not beating on the coin too much,or it will let the coin slip. Good thing is that the delrin does not mar the coin in any way, Maybe a delrin insert by different coin sizes inset to a bronze / brass base unit |

|

#48

|

|||

|

|||

|

Kurt,

When you have some please put me down for one! Please PM when ready to sell! Boris |

|

#49

|

|||

|

|||

|

I don't cut coins, but I've greatly enjoyed reading this thread from an engineering/inventor perspective. Great fun and it was good to see Rube Goldberg again, too. A thought: The biggest issue people seem to be having is with coins coming loose or being marred or both. I think Kurt's original design is pretty good, myself, but for several things. It's aluminum, the edge is thin, and the center hole is too small. The small hole means much force to clamp it, the thin edge means that the (flimsy by nature) aluminum will flex under pressure. Brass, bronze or even steel will be much more rigid, inherently.

Then: You have a metal-to-metal clamp. You can squeeze the nickel as hard as you want and it won't go anyplace, but either the clamp will flex or it will mar the coin or both. Aluminum will flex, steel will mar the coin. One solution is to make the top surface wide aluminum (like 1") so it can't flex. Another is to make it all out of something softer than the coin, like Delrin, but again it would have to be wide to prevent flexing. If you bear down on that first picture enough, that aluminum rim will literally move. IMO the ideal design would be a steel clamp with either "O" rings or a felt ring set into a matching groove (1/2 in each clamp part, of course)- the strength of steel (could be brass, I guess) with a buffer and also a material that provides a grip under pressure. Strength AND grip AND safety. But that's a $250 clamp.... Well, I just enjoy the mental challenge - ignore me if you like... |

|

#50

|

|||

|

|||

|

I'm a machinist, and I've got a cheap and unbelievably easy solution that will work for many needs:

Use a low melting point bismuth alloy to basically mold a custom vise for each coin. It's often called "Field's metal", and make sure you get the non-toxic variety. It will melt in hot water, and you can literally hold it in your hand while it's molten. The bismuth expands when it cools, so if you do it right, it'll get a tight grip on the edge of your coin. It'll take some experimentation to get this right, but you can remelt and start over if it isn't working. Here's how I'd try it first: 1. Place your coin engraving side down on a very soft silicone mat. 2. Place a short (1 inch?) piece of square pipe centered over the coin that's at least 3 times the diameter of your coin. Bigger means less flex and more clamping power on your coin edge. 3. Place a piece of scrap metal on top of the coin to weigh it down and press it slightly into the soft mat. The heavier the weight, the higher the coin will lift above the molten "vise", and the better the rim sealing to keep the molten metal off the face of the coin. The trick here is to keep from tilting the coin too much (a big deal for machining, but not so much for engraving), and to not cover up too much of the coin with the weight so that the molten metal can flow into and grip the design details of the coin for extra holding power. 4. It might be a good idea to weight down the square pipe a tiny bit only if your molten metal leaks out. 5. Melt your metal in some hot water (or whatever way is convenient) and pour it into the square mold you just made! 6. Once it's cool, you'll have a square metal block with a coin face sticking out the top of it. The square shape makes it easy to clamp into your engraving vise. 7. You'll have to get creative to make this setup cost more than $100, and you can do it with any kind of part you want. You'll be able to engrave things that were too small, delicate, and oddly shaped before you had this technique. 8. Have fun, and answer all my newbie engraving questions! 9. Here's some links: http://en.wikipedia.org/wiki/Field's_metal http://www.google.com/search?q=fixturing+alloy Buy it here: http://www.mscdirect.com MSC #: 00263590 10. For edge engraving, try wrapping the coin in a silicone mat tube so that if you look in the ends, you see the coin faces, then pour your molten metal in each end, and stuff something flat in there so when it cools, it'll have a nice flat face on the metal block. When you remove the silicone wrapping, be careful not to seperate the two halves from the coin faces, and now you can clamp it into a kant twist clamp or a vise, or whatever withoight damaging the coin face, and you'll have access to the entire edge of the coin. This method requires more thought and experimentation, but you could end up with better results than any other method that requires you to put clamp pressure on the faces of the coin. For that I'd clamp with sandpaper, but that'll damage the coin. Try cotton cloth, hard rubber, or plastic in a C clamp if it gives you rigid enough holding for engraving purposes, with no marks, and full access to the edge in one setup. That #10 was an after thought, so I have no idea how well it'll work for engraving. But, if you engrave the edge first, the molten fixture will grip the coin very tightly, for when you engrave the face. I bet some of the machinists here could put together an excellent coin engraving fixture kit with the info I have here, along with a pre-fixtured coin! Wouldn't that be cool? Last edited by qwasty; 04-07-2009 at 02:30 PM. Reason: messy #10 |

|

| Bookmarks |

|

|